Maybe something along the lines of a ship builder's scarf joint would apply here if you don't want to use splines.

You could simply scarf out both sides of the neck and use a fill shaped like the cut and then just finish over. You could just cut it to go around the truss rod. It'd be a big chunk of wood but it's be pretty solid provided you do a good job of joining the sides.

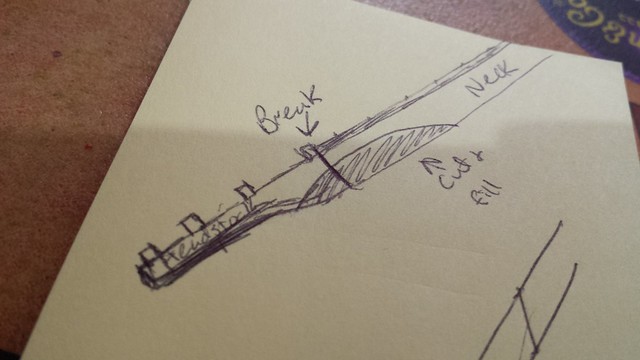

Just thinking out loud, Here's a drawing to illustrate what I'm suggesting. I've only done it on smaller things but not a neck. Be worth a shot at least to save it.